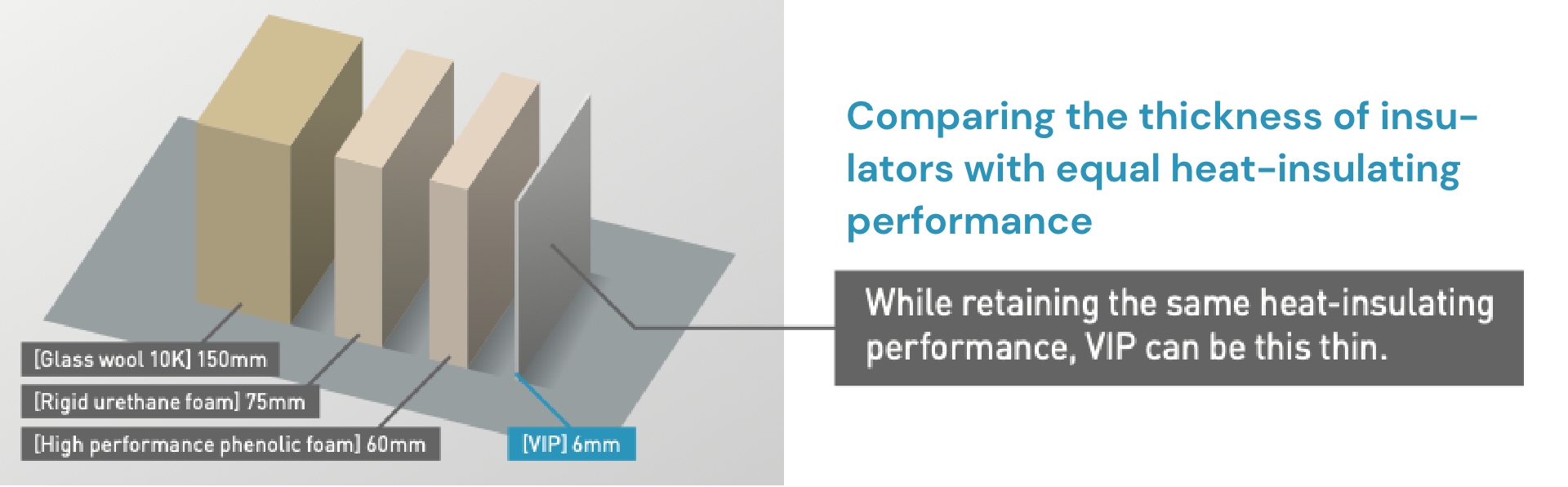

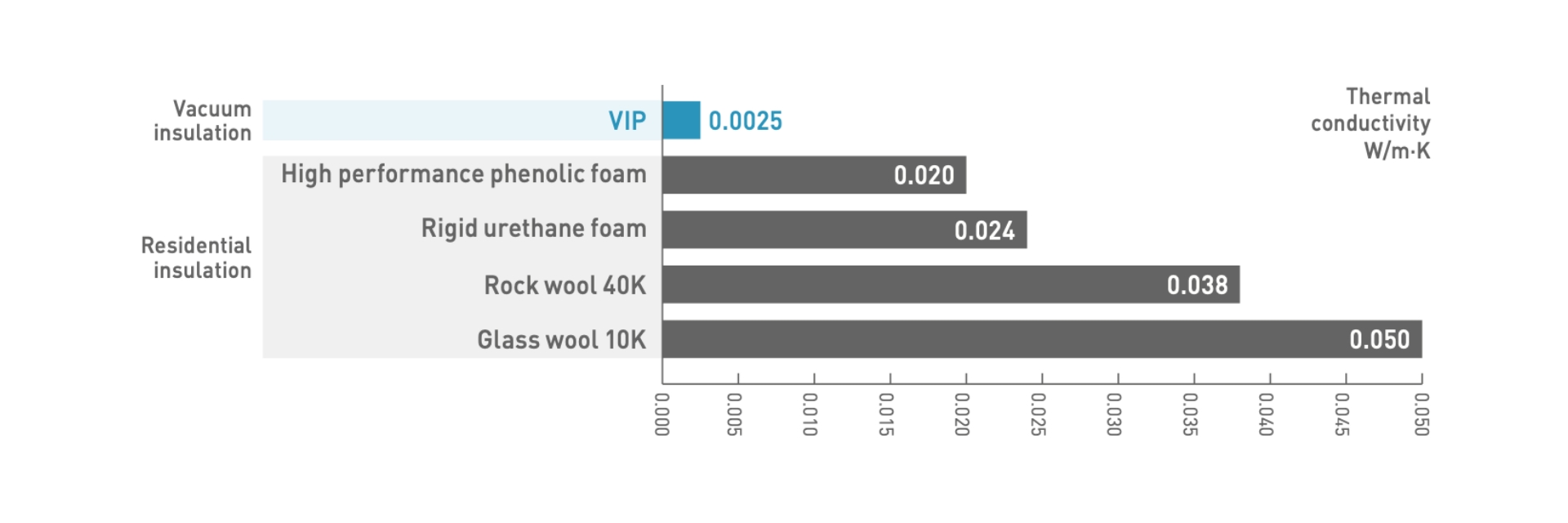

VIP offers the lowest thermal conductivity of any current insulat- ing material. It is thin enough to provide sufficient insulation in small spaces and thick enough to ensure reliable fixed-tempera- ture transport. We flexibly respond to customer needs and produce customized products. We offer VIP for insulated boxes for transport, EcoCute, and other various uses.

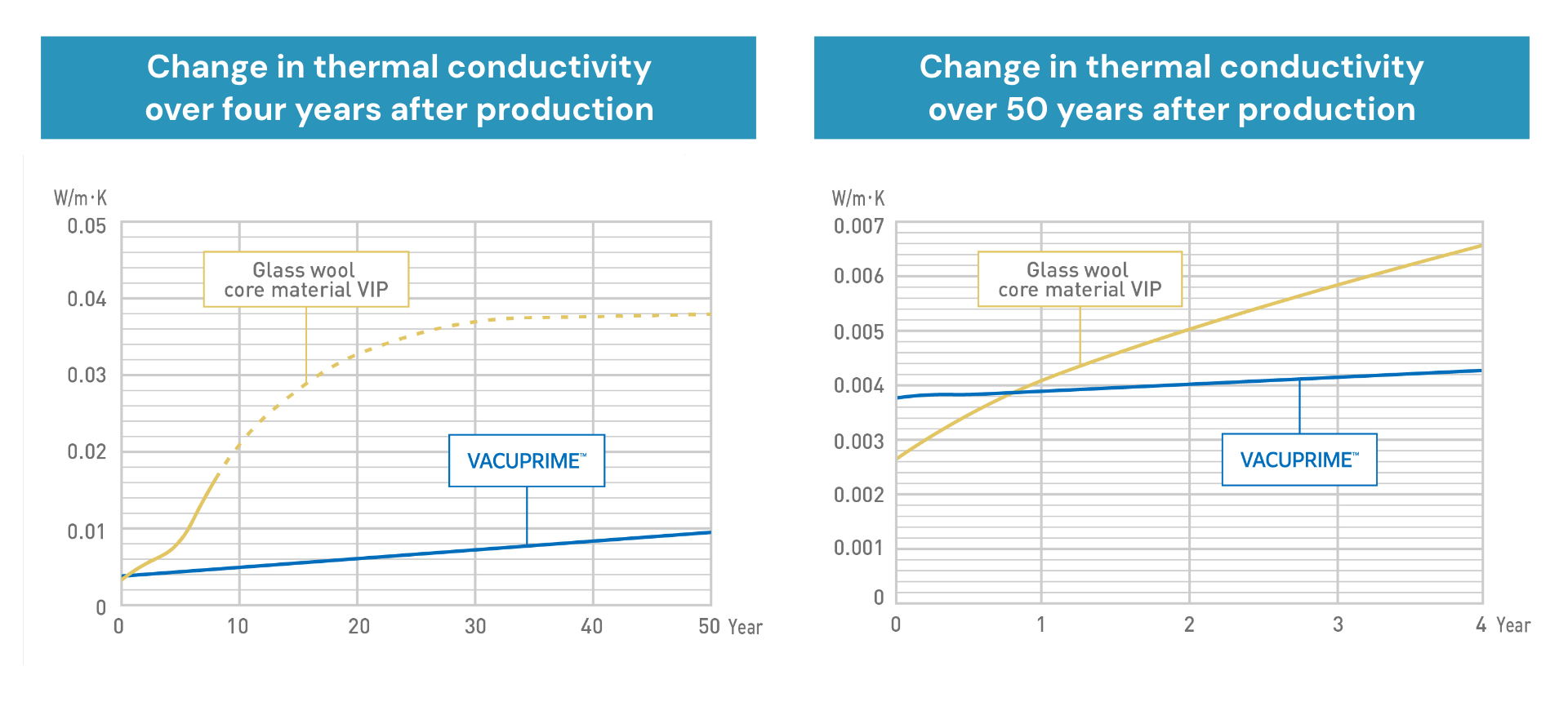

One of the weaknesses of vacuum-type insulation is the deterioration of performance due to a decrease in vacuum.

By using silica as the core material, with VACUPRIME, we have achieved a significant increase in service life in comparison to conventional glass wool core vacuum insulation.

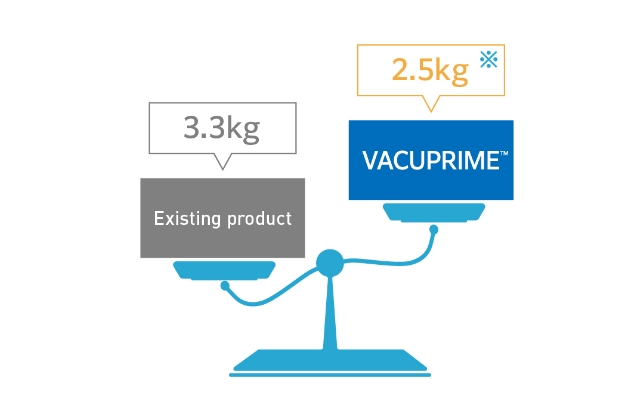

Another weakness of vacuum-type insulation is the weight of the product.

(*Comparison of the weight of vacuum insulation in 500x400x300 mm insulation boxes (comparative research by WACON))

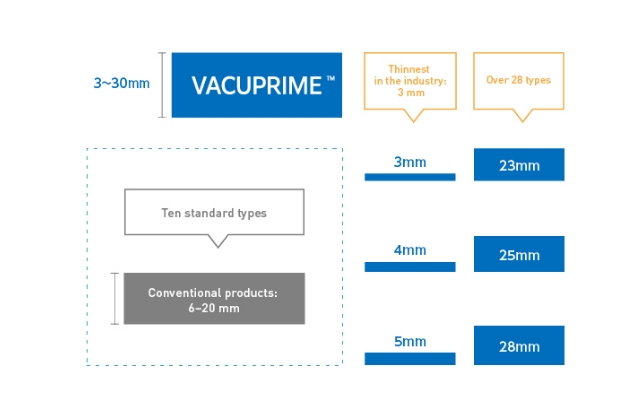

Due to manufacturing methods and raw material constraints, conventional glass wool core vacuum insulation can only be made with a prescribed thickness of 6–20 mm.

Using a special manufacturing process, VACUPRIME can be manufactured to any thickness from a minimum of 3 mm—the thinnest in the industry—to a maximum of 30 mm.

This is ideal when insulating with limited space due to layout constraints.

(Lot-size restrictions apply for some thicknesses.)

| Main core material ingredient | Silica |

|---|---|

| Appearance | Silver |

| Thermal conductivity | 0.0035w/mk(Thickness 25mm) |

| Initial internal pressure | ≦500pa |

| Density | ≦180kg/㎥ |

| Maximum temperature | 60℃(Heat-resistant specifications are also available. Please contact us separately.) |

| Humidity tolerance | 0%~70% |

| Maximum dimension | 1800×1000 mm |

| Minimum dimension | 250×200 mm |

※Thermal conductivity is a measured value, measured at the center of the panel, under the indicated conditions.

※Long-term thermal conductivity and internal gas pressure performance varies depending on panel size and thickness.

※The above data are representative values obtained under specific conditions, and are not standard values.

Other Products